Lilly Diabetes Summit Sequel: A 2013 Peek at Insulin Giant's Workings

For the second year in a row, I attended the Lilly Diabetes Blogger Summit in Indianapolis last week and experienced up close and personal the place that's been making the insulin that's been keeping me alive for almost 30 years.

This was the sequel, so to speak, of the first Blogger Summit the pharma giant held in 2012, hosting a dozen diabetes bloggers at the company's huge headquarters in Indy (where I live). But unlike the intro event last year that was more of a "get to know you," this second summit dug a little more into what Lilly Diabetes is doing "behind the scenes" and their efforts to better listen to our D-Community.

Lilly could do a lot better in sharing its work with PWDs. They seem to understand that, and I think they would earn a ton of good will if they were more communicative about what they're doing to help us pay less for insulin, for example.

In any case, those able to attend along with me April 29-30 were: Scott Benner, Adam Brown, Leighann Calentine, Kelly Close, Bennet Dunlap, Scott Johnson, Kelly Kunik, Cherise Shockley, George Simmons, Lorraine Sisto, and Kim Vlasnik. Many of us were live-tweeting using the hashtag #LDSummit13.

On the first morning of the event, we all went around the table and shared one word about our hopes for how we'd feel about this year's summit: productive, collaborative, energized, excited, educated, full, positive-progress, informed, hopeful, empowered, connected, re-connected, partnering in positive relationships, and inspired.

At some point during or after the event, I'm pretty sure I could describe myself feeling every one of those words. Still, I remain a little skeptical and disappointed on a few fronts.

Here are some of the "meatier" highlights of what was covered at this year's event (warning: it's long, because we covered a lot).

Those Disney Diabetes Books

We once again got an update on the books that Lilly Diabetes and Disney Publishing have been creating, which currently remain available only through doctors' offices. (Boo)

But Matt Caffrey, Lilly's product brand director, told us that in the third quarter, the existing books will be digitized so anyone can view them online. They won't be downloadable or available on Kindle or Nooks, though. Online access is great news, since many have said their HCPs don't have or know about the books, some doctors won't accept them from a Pharma company, and some PWDs feel uncomfortable asking to take one of the small supply when a newly-diagnosed family might really need them.

Actually, our D-Blogger group made the recommendation to put them online a year ago at the first summit. So you do have to wonder why it hasn't yet happened yet, and is still going to take another few months? The answer is that they are so big, and the industry is so regulated, that even little moves can take a long time for Pharma. On that note, there was a running joke at the summit that as we were being briefed, there was probably a group of compliance officers lurking just downstairs to keep tabs on us.

Lilly also told us that they're expanding reach of the printed books to the global market. They'll be translating the books into 17 different languages and making them available in 18 countries outside the U.S. Just like in the States, PWDs and families can obtain the books through healthcare professionals and eventually online starting later this year.

Lilly is also planning to launch two new Disney books for the tween years (ages 9-13) at the Children With Diabetes Friends For Life Conference in Orlando in July, along with Disney Family magazines focusing on diabetes. The new books will be "hot off the press" this summer and given to pediatric healthcare professionals starting in August, and Lilly tells us the second wave of books will likely be put online in early 2014. We're told there's also a third wave of Disney books planned, and those will likely coincide with the FFL 2014 conference.

While the books are good news, the way Lilly handled this topic was less than ideal; while our group was given an "inside scoop" on this news, and we saw the titles -- we were specifically told not to release any details on the books we saw because the "news will break" at the FFL conference this summer. To me, that's counterproductive: you bring in a group of D-Advocates to share these initiatives, knowing that people follow our blogs to share in community news, and then you put the muzzle on as far as specifics?! Bad PR move, Lilly.

It's the equivalent of holding a press conference to announce that you'll be making an announcement a few months down the road... Not impressed.

Touring R&D Labs, Insulin-Making Campus

After a few morning talks, we took a shuttle from the Alexander Hotel to Lilly's impressive main campus, complete with a Life Center with soccer and track fields, workout gym and hangout area -- to encourage employees to "engage, communicate and keep fit." There, we got a peek into the labs where two-thirds of the Lilly employees research the medicines and work on product development.

On the second morning, we took a shuttle over to the west side of Indianapolis to what's called the Lilly Technology Center, where the actual insulin-making happens. We were told this was a pretty special deal, as it was the first time Lilly Diabetes had allowed any patient group inside to see the manufacturing process first-hand!The manufacturing site is a whole campus unto itself, the size of 18 football fields, housing two-dozen buildings where they make three different vial sizes of Humulin and Humalog insulins. Some Humalog is also made at a facility in Puerto Rico.

"It's like sculpting," Dr. Fionnuala Walsh, senior VP of global quality, told us in an overview of the insulin-making process. "Picture a big block where you chip away to create an insulin product, rather than painting where you are creating or adding things to a canvas."

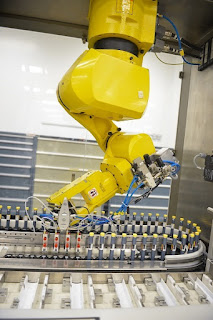

During the insulin-making process, there are thousands of quality checks and safety precautions weaved in. That happens through constant checks of equipment and product, from human inspections to computer analysis to photos being taken and examined at every step of the way. From the production floor, there are hundreds of thousands of environmental and safety checks done each year, dozens on each shift alone. From a mechanical arm grabbing vials every so often for random inspections to forced-safety checks that involve creating an environment within the vials to see if any bugs would grow if given the chance.As Dr. Walsh puts it: The insulin (manufacturing) process is like having a second-by-second accurate CGM reading of your blood sugars that pretty much never fails. How cool!

We heard during the overview that a batch can supply roughly one million PWDs, but the specifics on insulin production amounts were "proprietary" and off the record. Again, boo. Why invite bloggers in to make them privy to things that are secret, but would be key pieces of information the D-Community would want to know?

What we did learn "on the record" was that a single kilogram of insulin crystals will create enough insulin to supply the needs for approximately 2,000 people with diabetes for a year. We also learned that the process starts with a line of (non-contagious) E. coli -- as opposed to Novo Nordisk that uses yeast as their starting material. They start off with 50,000 liters of this E. coli and by the end of the process have 7-8 liters for the final product. I also saw some specific figures and numbers inside the facilities on the plant floor, but we weren't allowed to take photos.

Getting suited up in flocks, shoe-covers, gloves, safety glasses, and hair nets took us into the inner workings of the insulin-manufacturing facilities. We could hear insulin bottles clinking on the production lines and see them speeding along, a dozen passing by per second being filled with Humulin (at that time) and then getting carted off to get their orange (or purple) plastic caps attached. Two fully-suited workers (looking like foot soldiers) sit for 12-hour shifts, just keeping watch over the production lines and waiting for any alert that might signal something is wrong.

Once the vials are filled and capped, they end up with a sort of photo shoot at the end of the line -- a total of 10 pictures from every angle is taken of each vial, and analyzed by a computer to detect any possible cracks or product flaws. Then, they are sent off for boxing and labeling.

Dr. Walsh told us, "We almost never fail a batch, and it would be a huge shock to have one not get through. We have a lot of confidence that it will always be right, but we never get complacent. We know there's a lot of variability in your diabetes... But what we want is for one thing to be the same: the quality of your product."

We also saw pen-cartridge labeling machinery, at work on cartridges brought in from Lilly plants where they're made in France and Italy (but will soon be added to the Indy plant). That labeling process takes only 5-10 minutes, and it was interesting to learn that different countries have varying requirements for how these products must be packaged -- not only language differences, but Brazil for example requires a manufacturing date to be stamped onto each pen. (Hey, FDA, why isn't that required in the U.S.?) All in all, there are 150 different combinations of drugs and literature being assembled here.

The company's also building a new 84,000-square-foot facility that will allow Lilly to make those insulin cartridges right in Indy that are now made overseas and shipped here for labeling and distribution. I was on hand for the christening of that $140 million plant last November, and it was interesting to see the progress since then and get a look inside where the pen products are made.

Cost Benefits for PWDs?

Lilly officials told us that construction to expand capacity and improve operational efficiency in insulin production will allow us PWDs to see a consumer cost-benefit.

Key to saving money is adopting more common technology platforms, which will allow them to basically modernize the whole manufacturing process and maintain quality. They expect to double their manufacturing capacity by 2016 and 2017, the spokes-folks told us

Of course, the company wasn't able to provide dollar figures on what the reduced-production-cost-to-consumer ratio might look like. We all just need to keep this promise in mind so we can protest loudly if we don't seeing prices dropping in the next four years, right?

In the Pipeline

Patty Martin, senior director of Lilly Diabetes strategy and operations, gave us a run-down of the company's D-pipeline in the coming years that includes a number of new medicines for both type 1 and type 2.

To elaborate, we also had a roundtable discussion with various Lilly officials, who told us about their plans for developing new basal and fast-acting insulin. The details are a post in itself, but one fascinating note was how Drs. David Moller and David Kendall both insist that smart, glucose-responsive insulin is "aspirational and over-hyped on timeline," and that faster-acting insulin is what's next in the coming years.

With Humalog coming off patent this year, the Lilly folk didn't seem too worried about a sudden influx of generic insulin because of the "complicated" manufacturing process that will ostensibly hinder competitors -- along with the little guidance the FDA has given at this point on biosimilars. But again, topics for a separate post... Right now, they have about a dozen products in Phase III clinical trial research that's the result of about 15 years of research and development. The next 2 to 5 years will be a key time for market availability on these products, they told us.

In talking about these products, D-blogger Bennet Dunlap urged Lilly to work with doctors more on communicating that insulin can be a way to succeed in D-management, rather than using a "treat to fail" approach in resisting insulin treatment. Lilly's Patty Martin acknowledged they haven't done that well, and they plan to improve.Lilly CEO John Lechleiter stopped in and chatted with us for about 30 minutes at the R&D building, too, and it was cool to hear his thoughts on the pipeline. Long-term, he sees smart insulin/more mixable insulin/diabetes technology changes making significant impact 10 years out. In the meantime, what keeps him up at night? How to keep the company's R&D sustainable with continued cost-cutting. The company saw a boom in development in the late 90s, but hasn't seen any new monumental developments like Humalog since. Right now, the biggest concerns he sees industry-wide are how health care reform will influence medical professionals' reimbursement scheme and how we can keep up with the aging population.

"This is not the time to cut back (R&D) budgets," he said. "We have to make sure we are not squashing medical innovation in the process of budget-deficit reductions and push to lower costs."

Doing Good, Communicating Well

Remember before going to this event, we called on Lilly hosts to end each presentation with, "and this benefits people with diabetes by..."?

What we learned is that they are actually doing a lot of good works for the community, but doing a pretty poor job of getting the word out about these efforts. Lilly acknowledged this gap, and has been beefing up its social media presence in the past year, they told us.

Some good works include: Lilly's involvement in initiatives like Project Hope and the Life for a Child program; emergency preparedness; how it offers scholarships through the Diabetes Scholars Foundation to send families to the Children with Diabetes FFL summer conference; and a Non-Communicable Disease (NCD) partnership, where Lilly is spending $30 million over five years to conduct a public health research project in Brazil, India, Mexico, and South Africa about how D-Care is delivered in those countries and what can be done with local organizations to help improve that care.

To be better communicators, the LillyPad blog recently started accepting comments (!), and they've been more interactive on Twitter. They've also created a new Twitter feed recently, specifically to engage with media and patient-bloggers like us. They're also planning to announce yet another Twitter feed soon, dedicated to the ADA Scientific Sessions announcements they'll be making this June.

The company is also using Spoonful.com to tell diabetes stories, and they're creating a microsite later this year that aims to be a "one-stop shop" for online access to books, articles, program information, and many other aspects of what Lilly Diabetes does. (Move over, Sanofi's "The Dx" site?)

We echoed what we've told many about social media: it's a two-way conversation, and robo-tweeting without any interaction isn't cool. Don't push products or your company, just get us valuable information to share and make connections where needed.

• Is there any talk of redesigning Glucagon to look more like an EpiPen, to possibly address any resistance in schools/parents using this?

Official Answer: Lilly recognizes the need and benefit for having a simpler way to use Glucagon, but they also want to make sure the instable nature of the molecule isn't overlooked in the manufacturing process. Right now, it's unstable after a few hours in liquid form. That's why the company has made the two separate containers with powered glucagon and a sterile liquid, so it can have a 24-month shelf life. Lilly's looking to make it easier to use, but there's no timeline update on that.

Our take: they either don't have a business incentive to pursue this, or whatever they're working on is another company secret. Let's all cross our fingers that the small company developing GlucaPen is making good headway!

• Does Lilly have any plans to create something like Pendiq (digital insulin pen) here in the States?

Official Answer: "Adding electronics to a device doesn't always translate to simplicity -- but it can be done. It's quite likely that new devices will continue to incorporate electronics, and we are focusing on making sure the benefits provided offer simplicity (and safety) to the user."

Our Take: Not right now... perhaps they're waiting to see which types of integrated devices really take off.

We appreciate you hosting this event, Lilly Diabetes, and for proving that you are making efforts to listen to our D-Community. Personally, I'm looking forward to continuing to help connect people with any and all resources that can help them live better with the Big D.

Disclosure: As with other similar pharma summits, Lilly paid for bloggers' travel, accommodation, and food for this event. Though I didn't stay in the hotel as I'm local, Lilly paid for my parking. We each received a goodie bag that included snacks, mints, hand sanitizer, local tourist info about Indy, and a picture frame for our summit photos.

- - - - - - - - - - - - - -

Originally published at DiabetesMine on May 6, 2013

Comments